ChemEng08 : ONLINE WEBCASTING!!

Saturday, October 25, 2008

Just to share a quick information that I received from IChemE Facebook - posted by Tanya Graham about thee ChemEng08 held in Birmingham.

Not being in Birmingham, UK at ChemEng 08 doesn’t mean you have to miss out on the biggest IChemE event of the year!!

For just £20.00, from wherever you are in the world, you can tune in LIVE to the ChemEng08 webcast and view all of the main sessions from the Global Forum Theatre.

After the event, as part of the online registration fee, you will also have online access to view over 15 of the sessions from the technical programme.

Wednesday highlights include: Opportunities and Challenges of Emerging Markets (Chaired by David Smith, Economics Editor at the UK’s Sunday Times); Education and Skills – Bridging the Gap (Chaired by Colin Grant, Dean of Engineering at University of Strathclyde); and seminar programmes dedicated to Health, Safety & Environment; Sustainable Technology; and Energy.

Thursday opens with IChemE President, Professor Richard Darton delivering his presidential address before the Global Forum Debate – Chemical Engineers believe the world needs more innovation and less regulation. Appearing on the panel are Judith Hackitt, Chair of the UK’s Health & Safety Executive; Nigel Hirst, Managing Director of Haden Freeman Ltd; Ian Shott, IChemE Deputy President and President & Chief Executive of Excelsyn; and Peter Davidson, Innovation Advisor at BERR and DIUS.

Other Thursday highlights include an update on the progress of the Institution’s Technical Roadmap by IChemE Chief Executive, Dr David Brown; and seminars programmes dedicated to Food & Drink; Water; and Biosystems.

Registration is £20, check this amount in your local currency at: www.finance.yahoo.com/currency

The webcasting is open to both members and non-members of IChemE.

To register for the ChemEng 08 webcast, go to www.chemeng08.com

Be the best chemical engineer you could be. Learn something about chemical engineering that's not inside your textbook. Subscribe to the content of this blog.

Labels: Chemical Engineer, Chemical Engineering, Learning Curve, Seminar

posted by Kipas Repair JB @ 10:11 AM,

,

![]()

Premiership Footballer Wants to be A Chemical Engineer

Sunday, October 19, 2008

It's a fact that playing football in Barclay Premier League (BPL) must be very lucrative. However STOKE star Seyi Olofinjana has a different view of it. He wants a new career in the later when he retire from football. He wants to join the oil industry.

The 28-year-old midfielder already has a degree in chemical engineering and wants to top that.

He is paying 12,000 pounds sterling for a distance learning course in subsea engineering with Aberdeen University and hopes to work in the huge oil industry back home in Nigeria one day.

Middlesbrough is not a dream day out for many people — but the chemical plants of Teesside could provide a glimpse into Olofinjana’s future.

Middlesbrough is not a dream day out for many people — but the chemical plants of Teesside could provide a glimpse into Olofinjana’s future.

He said: "I could be working out on the oil rigs when I’m 35, you never know."

The key thing is to get myself prepared. You need to fall back on something. No matter how well you do in football, it’s not for ever.

Source: The Sun NewspaperIt's very interesting to know that a professional footballer like Seyi have an interest and degree in chemical engineering and looks forward on his new career later. Not a lot of footballer will have radical career plan change like him. Let's just see his new career after retiring from soccer.

My 2 cents: I hope he'll be a successful chemical engineer (and hope to see him wear coveralls and safety helmet...).

More information about Olafinjana's profile as a footballer:

Wikipedia.org/wiki/Seyi_Olofinjana

4thegame.com

-----------------------------------------------------------------------

FREE Technical Magazines - Chem-Eng.Tradepub.com.

Join Chemical Engineer Rocks FACEBOOK Group...

Apply Chemical Engineering Jobs online - Updated daily... :)

Be the best chemical engineer you could be. Learn something about chemical engineering that's not inside your textbook. Subscribe to the content of this blog.

Labels: Chemical Engineer

posted by Kipas Repair JB @ 9:55 PM,

,

![]()

Pinch Valve Sleeves

Saturday, October 18, 2008

Many industries use specific valves, called pinch valves, to control fluids, waste water, slurries, abrasives and corrosive chemicals. Pinch valves are constructed of a heavy-duty, rugged pinch mechanism that positions a sleeve. The valve offers maximum durability and ensures precise flow control in many industrial processes.

Inside every pinch valve is a sleeve that is crucial to the performance success of the valve. This sleeve enables a pinch valve to have a bi-directional, drop tight shut off with which to control flow. Most pinch valve sleeves are made of flexible elastomer compounds, many of which resemble rubber in composition and feel. Because a sleeve's composition is crucial to the success of the valve's application, valve manufacturers offer different elastomer options from which the sleeve can be constructed.

The many uses of the pinch valve

Because pinch valves are useful in a wide range of industries, the ability of a purchaser to choose the desired sleeve composition is paramount. Commonly used in the mining industry, a pinch valve's tough construction makes it ideal for use on harsh and abrasive mining slurries. Pinch valves can also be useful in demanding wastewater treatment applications. For example, a pinch valve's accurate, repeatable linear flow control and drop tight, bi-directional shut off make this valve type a good choice for sludge and raw sewage control.

In the power industry, pinch valves are an important component used in lime and ash handling - two tough services commonly found within a power plant. The abrasion-resistant, self-cleaning, and flexible elastomer sleeve of a pinch valve won't scale, bridge, plug or freeze on slurries. Pinch valves can also work in the treatment and handling of corrosive chemicals. Because there is no packing to maintain and no cavities, seats, or cam action to bind valve operation, pinch valves are often used in corrosive chemical applications.

Pinch valves can also be used in pulp and paper mills. Pulp stock, coating and recycled paper lines are some of the most difficult applications for a valve. The flexible elastomer sleeve of a pinch valve are able to withstand these abrasive services. Pinch valves can also be a great asset in food and beverage plants, cement/sand/silica factories, refineries, pneumatic conveying, and scrubbing.

A sleeve elastomer for every application

The multitude of uses for pinch valves require that purchasers be able to choose specific sleeve compositions and styles for various applications. A pure gum rubber sleeve, for example, is not suitable for the handling of strong acids, but might be appropriate for food manufacture or alcohol distillation. The application of a particular pinch valve, including the temperature range to which it will be exposed, dictates which sleeve elastomer a valve customer should choose.

Pure gum rubber sleeves are resilient and abrasion-resistant. They can handle an incredibly wide temperature range, from -50 F to 180 F, and they are extremely flexible, as well as non-marking. They are composed of natural rubber, and are most suitable for organic (or, carbon-based) acids, and mild chemical compounds, including alcohols. Strong acid and basic solutions, oils, and solvents are some of the chemicals that this type of pinch valve sleeve is ill-equipped to handle.

Neoprene pinch valve sleeves are synthetic rubber sleeves composed of chloroprene polymers. They handle a slightly wider temperature range than pure gum rubber sleeves do, working well with temperatures up to 220 F. Neoprene is chemically inert, and works best in the handling of moderate acids and other chemicals. Unlike pure gum rubber, it is strong and resilient enough to handle products containing ozone, as well as some oils and fats. Neoprene is more resistant to abrasion than is gum rubber; however, it can be eroded or weakened by oxidizing acids, ketone, ester, and chlorinated hydrocarbons.

Sleeves composed of chlorobutyl elastomers, or chlorinated butyl rubber compounds, handle major temperature ranges, from -60 F to 300 F. These sleeves are known for their good abrasion resistance and their ability to handle animal and vegetable fats. However, other types of oils are too heavy for chlorobutyl elastomers to handle -- as are solvents, which can break down the rubber.

The trademarked name of nitrile (a triple-bonded carbon-nitrogen compound), Buna-N can be used to make sleeves suitable for -40F to 240 F temperature ranges. These types of sleeves can be useful in chemical manufacture and chemical engineering because they can handle chemicals and solvents. They are not suitable, however, for ozone, ester, ketone, or nitro/chlorinated hydrocarbons. Meanwhile, Hypalon, a trademarked name for a chlorosulfonated polyethylene compound, is used to construct sleeves suitable for temperature ranges between -60 F and 275 F. This durable compound can handle quite strong acids and bases, as well as freon, ozone, alcohol compounds, and alkalines. This type of pinch valve sleeve should not be used with ketone, ester, or various aromatic and chlorinated hydrocarbons. Hypalon resists weathering quite well, however.

EPDM (or ethylene propylene diene monomer) valve sleeves are excellent for use with fats and oils. These valves -- made of the material used to seal vehicle doors, windows, and the like -- can withstand temperature ranges between -60F and 300F. They should not be used, however, to work with mineral oils or solvents. They also weather well. Viton, a type of synthetic rubber used commonly in O-rings, can also be used with animal and vegetable oils, as well as with acids. Though this type of sleeve performs poorly at temperatures lower than -10 F, it performs quite well at temperatures up to 400 F. Viton sleeves also display excellent tensile strength.

Each of the many uses of pinch valves requires careful consideration of the valve sleeve that is most appropriate to the process for which the valve will be used. With the variety of sleeve elastomer options available, it is no wonder that pinch valves are applicable in so many situations and for so many processes.

Red Valve, in Pittsburgh, Pennsylvania, manufactures custom pinch valves, including air operated, control, and manual pinch valves, along with pinch valve sleeves. For more information, visit Red Valve's Web site.

-----------------------------------------------------------------------

Convert You Car To Burn Water + Petrol = Double Your Mileage!

High Conversion, Few Refunds, Due To Huge Demand: Soaring Gas Prices Compel People To Save Gas!!! Popular D.i.y Watercar: Run Your Car Partially On Water, Reduce Emissions/Global Warming! Practical Free Energy Based On 1000s Of Real CarsWorldwide!!!

Join Chemical Engineer Rocks FACEBOOK Group...

Apply Chemical Engineering Jobs online - Updated daily... :)

Labels: Learning Curve, Valve

posted by Kipas Repair JB @ 12:03 AM,

,

![]()

Chemical Engineer Elected As UTM New Vice-Chancellor

Tuesday, October 07, 2008

The guessing game is finally over after the new Vice-Chancellor of Universiti Teknologi Malaysia (UTM) is elected. Datuk Prof. Dr. Ir. Zaini Ujang, 43, is officially the new Vice-Chancellor of UTM, replacing Tan Sri Professor Dr Mohd Zulkifli Tan Sri Mohd Ghazali, whose tenure ended on the 30th of September 2008.

Datuk Zaini, a chemical engineer, joined UTM in 1988. He was the director of the Water Resource and Environment Institute from 2001 to 2006 and promoted to deputy vice-chancellor last year. More news:

More news:

NST

Bernama

Topix

MALAYSIAN CHEMICAL ENGINEER Zaini Ujang has been appointed vice-chancellor of Universiti Teknologi Malaysia (UTM). The role begins immediately and lasts for three years. At the age of 43, he is billed as the youngest person to lead a Malaysian public university.

Zaini served UTM as deputy vice-chancellor for research and innovation from March 2007. Prior to that, he was dean of UTM’s Faculty of Chemical and Natural Resources Engineering, beginning July 2006, and director of UTM’s Institute of Environmental & Water Resource Management from 2001 to 2005.

On receiving the post, Zaini said: “I thank the government for being bold enough to appoint a relatively young person to the post of vice-chancellor. I will aim to improve the standard of higher education and implement the National Higher Education Strategic Plan.” This aims to improve Malaysia’s competitiveness, productivity and innovativeness.

Zaini received his undergraduate degree in chemical engineering at UTM, and went on to complete an MSC and PhD in environmental engineering at Newcastle University, UK. He began his academic career at UTM in 1988. He is lauded as a Malaysian expert in matters concerning water and wastewater treatment, and has held posts advising the government’s education department.

News is adopted from TCEToday.

-----------------------------------------------------------------------

Convert You Car To Burn Water + Petrol = Double Your Mileage!

High Conversion, Few Refunds, Due To Huge Demand: Soaring Gas Prices Compel People To Save Gas!!! Popular D.i.y Watercar: Run Your Car Partially On Water, Reduce Emissions/Global Warming! Practical Free Energy Based On 1000s Of Real CarsWorldwide!!!

Join Chemical Engineer Rocks FACEBOOK Group...

Apply Chemical Engineering Jobs online - Updated daily... :)

Labels: Chemical Engineer

posted by Kipas Repair JB @ 8:33 PM,

,

![]()

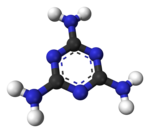

Melamine - What is Melamine?

Monday, October 06, 2008

Melamine combines with cyanuric acid to form melamine cyanurate, which has been implicated in the Chinese protein export."

Melamine adulteration of food products has made other headlines in recent years, including pet food recalls in Europe and the U.S. in 2007. It has also been employed as an additive to cattle feed to boost its nitrogen content, appearing in soy meal, corn gluten meal and cottonseed meal.

2. Anchor Wam Frootmilk Drink Mango Magic

3. Anchor Wam Frootmilk Orange Chill

4. Anchor Wam Frootmilk Strawberry Spin

5. Anlene Milk

6. Anmum Materna 180g

7. Anmum Materna Chocolate

8. Dutch Lady Pure Milk

9. Farmland Skim Milk

10. Greenfood Yili Pure Milk

11. Jinwei Drink

12. Jollycow Pure Fresh Milk

13. Jollycow Slender Low Fat Milk

14. KLIM Instant Full Cream Milk Powder 1.8kg

15. M&M Chocolate Brown 40gm

16. Meiji Hokkaido Azuki (red bean ice cream)

17. Meiji Ujikintoki (red bean and green tea frozen confection)

18. Mengniu Original Drink Milk

19. Mengniu Pure Milk

20. Milk Chocolate Bars/China

21. Milk Chocolate Candies?China

22. Milkboy repacked

23. Monmilk Breakfast Milk Walnut Milk Beverage

24. Monmilk High Calcium Low Fat Milk

25. Monmilk High Calcium Milk

26. Monmilk Milk Deluxe Pure Milk

27. Monmilk Pure Milk

28. Monmilk Suan Suan Ru Sour Milk Beverage (Mango flavor)

29. Natural Choice Milk Ice Bar

30. Nespray

31. Nestle Carnation Calcium Plus Non Fat Milk Powder (1.6kg)

32. Nestle Chocolate Flavor Ice Cream Cone

33. Nestle Dairy Farm Pure Milk

34. Nestle Vanilla Flavor Ice Cream Cone

35. Nutri Express Milk

36. Nutri-Express 15 Nutritional Elements (blue, red and orange label and cap)

37. Nutri-Express Milk

38. Nutri-Express Milk Green Apple

39. Prime Roast Cereals 28gm

40. Pura Fresh Milk

41. Snickers Brown 59gm

42. Strawberry Sorbet

43. Trappist Dairy Low Fat Yogurt drink

44. Vita Fresh Milk

45. Wahaha Orange

46. Wahaha Yellow

47. Want Want Milk Drink

48. Yili High Calcium 250ml

49. Yili High Calcium Milk 1L

50. Yili High Calcium Low Fat Milk Beverage

51. Yili Low Fat Milk 1L

52. Yili Milk

53. Yili Puremilk 250ml

54. Yili Puremilk 1L

55. Yinlu Milk Peanut

+60-3-88 83 35 03,

+60-3-88 83 36 52

+60-3-88 83 35 00

For further information or latest update on milk products tainted with melamine issue, please access Food Safety and Quality Division website under Ministry of Health Malaysia. Alternatively, please visit WHO website to better understand about melamine contamination.

To obtain the updated list of milk/dairy products that are not affected by melamine contamination by Food Safety and Quality Division, Ministry of Health Malaysia, click here.

I'm sorry but I'm not able to provide information of the approve milk/dairy product for all countries.

New tests on baby milk powder in China show no signs of melamine. The scandal that broke almost a month ago, is responsible for the deaths of four infants and sickening more than 54 thousand others. (Oct. 6). Source: AssociatedPress (AP).

One child has died and an official said the number of children sickened had risen to 432.

Investigators have detained 19 people and are questioning 78 to find out how melamine was added to milk supplied to Sanlu Group Co., China's biggest milk powder producer, officials said at a news conference. They said some tainted powder was exported to Taiwan but none was sent to other foreign markets.

In Taiwan, authorities seized thousands of bags of Chinese milk powder. The incident reflects China's enduring problems with product safety despite a shake-up of its regulatory system after a spate of warnings and recalls about tainted toothpaste, faulty tires and other goods.

The biggest group of victims is in China itself, where shoddy or counterfeit products are common. Infants, hospital patients and others have been killed or injured by tainted or fake milk, medicines, liquor and other products.

In 2004, more than 200 infants suffered malnutrition and at least 12 died after being fed phony formula with no nutrients. Some 40 companies were found to be making phony formula.

-----------------------------------------------------------------------

Convert You Car To Burn Water + Petrol = Double Your Mileage!

High Conversion, Few Refunds, Due To Huge Demand: Soaring Gas Prices Compel People To Save Gas!!! Popular D.i.y Watercar: Run Your Car Partially On Water, Reduce Emissions/Global Warming! Practical Free Energy Based On 1000s Of Real CarsWorldwide!!!

Join Chemical Engineer Rocks FACEBOOK Group...

Apply Chemical Engineering Jobs online - Updated daily... :)

Labels: Food, Health, Learning Curve, News, Problem, Video

posted by Kipas Repair JB @ 10:08 PM,

,

![]()

The Author

I’m Zaki. I used to be a project, process and chemical engineer. Few years ago I successfully became a Chartered Engineer (IChemE) and Professional Engineer (BEM). I'm now employed as a chemical engineering educator/researcher/consultant. Hope you like reading my blog. I welcome any feedback from you. My email: zaki.yz[alias]gmail.com. TQ!