Production Plant Problem

Thursday, November 29, 2007

Normally, there’ll be less or no problem when a production plant is running smoothly. The supervisors and plant operators will be happy taking care of a normal running plant. The executives and engineers will monitor and optimize the processing parameters and ensure all utilities consumption such as water, electricity, steam, air, chemicals, natural gas, LFO, diesel etc are kept at the lower side. Once in a while there’ll be some problems such as leaking mechanical seal in a centrifugal pump or the level transmitter signal is not showing the right reading. Well, those are just some minor maintenance problem and could be easily entertained by the fitters and technician.

In the next post, I’ll share 3 problems that we faced during our plant stopping and starting up last week, which made a lot of us miserable. You’ll learn these real problems that none of us ever expected it to happen. Check it out later…

Labels: Accident, Chemical Plant, Equipments, Experience, Fire, Learning Curve, Plant Shutdown, Problem

posted by Kipas Repair JB @ 12:32 AM,

,

![]()

2 Major Exhibitions and Conferences in 2 Countries

Friday, November 23, 2007

There will be two major events (Exhibition and Conference) coming on this coming week from 27 - 30th November 2007. One will be held in Malaysia while the other one will be organized in Singapore. Check it out:

BioMalaysia 2007 - Venue: Putra World Trade Centre (PWTC), Kuala Lumpur.

BioMalaysia 2007, Malaysia’s premier international biotechnology event, brings together biotechnology and life science professionals, executives, entrepreneurs, investors and policymakers from all over the world to connect, network, learn and exchange ideas. BioMalaysia 2007 is targeted at local and international biotechnology and life sciences attendees from all areas of the industry specifically in Agriculture, Healthcare and Industrial sectors.

BioMalaysia 2007 is targeted at local and international biotechnology and life sciences attendees from all areas of the industry specifically in Agriculture, Healthcare and Industrial sectors.

This year’s theme focuses on innovation, the driving force of biotechnology. Get new perspectives and insights on how the biotechnology and life sciences industry plays a crucial role in innovation economy, and what the unique opportunities and challenges are in bringing innovative discoveries to commercialisation in the global markets. Hear what the roadmap for an Innovation Economy in Malaysia will be. Featuring

Featuring

- Latest research findings

- State-of-the-art technologies

- New product launches and demonstrations

- Networking opportunities with local and international attendees

- Business and collaborative opportunities

- Production and research capabilities

- Media publicity opportunities

Agriculture, Healthcare and Industrial Biotechnology

CIA 2007 - Venue: Suntec Singapore, Level 4.

ControlsAsia2007 - The 15th International Plant Process Engineering Exhibition and Conference

InstrumentAsia2007 - The 13th International Instrumentation, Measurement and Testing Exhibition and Conference

AnaLabAsia2007 - The 11th International Laboratory and Analytical Technology Exhibition and Conference

CIA2007 provides an ideal platform for the sharing of ideas and building of new contacts among the industry leaders and professionals in controls & automation, instrument, testing, analysis and process engineering. Preregister Online at: www.cia-asia.com

Personally, I have attended the CIA2006 held in KLCC last year. I gained a lot of informations, ideas, knowledges and goodies. It will be great to attend the CIA2007 in Singapore. Unfortunately, I could not make it to either the BioMalaysia2007 or the CIA2007 due to job constraint. Hopefully I can visit such exhibition later in the future. I hope anybody attending the exhibition or seminar can share their experiences with us.

Discuss your problems at Chemical Engineering Forum

Labels: Biology, Biotechnology, Control System, Equipments, Exhibition, Learning Curve, News, Quality, Seminar, Training

posted by Kipas Repair JB @ 11:16 PM,

,

![]()

Monitoring Activities Via Surveillance Video

Wednesday, November 21, 2007

A processing or production plant is a place which does not simply belong to anybody. It is strictly for authorized personnels such as production executives, process engineers, supervisors, plant operators, maintenance fitters, contract workers and others. Inside a production plant, there are hundreds and thousands of equipments, instruments and machineries.

As a process engineer, sometimes I need to see and monitor what is going on inside the control  room or plant. It's easier to monitor the ongoing activities via a CCTV or a video surveillance system. There are moments where we need to check what the night shift was doing. There was also an occasion where a plant operator lost his handphone while charging it in the control room. After he realized his handphone was missing, he swiftly went to the place where the video surveillance is monitored to trace who took his belonging.

room or plant. It's easier to monitor the ongoing activities via a CCTV or a video surveillance system. There are moments where we need to check what the night shift was doing. There was also an occasion where a plant operator lost his handphone while charging it in the control room. After he realized his handphone was missing, he swiftly went to the place where the video surveillance is monitored to trace who took his belonging. I believe not all production plants or factories install their own video surveillance system. I seriously think they should install them at various strategic spots for security reasons and monitoring any suspicious activities going around the premises. Even offshore platforms in the oil and gas industry are installed with video surveillance system.

I believe not all production plants or factories install their own video surveillance system. I seriously think they should install them at various strategic spots for security reasons and monitoring any suspicious activities going around the premises. Even offshore platforms in the oil and gas industry are installed with video surveillance system. One of the best in the business of professional grade video surveillance systems is EZWatch Pro Video Surveillance. EZWatch Pro video surveillance systems are among the most reliable and popular computer based video surveillance systems on the market. The products are of the highest quality, great value and fully supported by the factory.

One of the best in the business of professional grade video surveillance systems is EZWatch Pro Video Surveillance. EZWatch Pro video surveillance systems are among the most reliable and popular computer based video surveillance systems on the market. The products are of the highest quality, great value and fully supported by the factory.

The EZWatch Pro video surveillance systems is packed with complete feature that customers want. These include Easy Remote Viewing and Internet Monitoring, IP Camera Integration, Pre Alarm Recording, Area Select Motion Recording, Object Tracking, Missing Object Alarm, Dual Monitor Display, PTZ Auto-Tracking etc. The emergence of this technology have created a smarter video surveillance. This behavior recognition software adds intelligence to video as it is captured, recorded and analyzed. On top of that, the intelligent video offers improvements in video image enhancement even in extreme darkness.

Combining the intelligent video surveillance and its analytics software, a predefined detection of violation which occurs are automatically, in the form of real-time alarms/alerts sent to their responders. This keeps security personnel from continually having to watch monitors, particularly during the bulk of their shifts, when nothing is happening on screens. Surprisingly, this high tech video surveillance system is very easy to use. Most of the customers never open their user manual because the on-screen programming is so simple. They just look at the screen and it provides the customer a clear understanding of how to use it.

With such a good set of video surveillance system, we can ensure a more safer and secured working place. It's an investment that should be made by asset owner for the benefit of his business. In fact I may consider to use one for my house, just for the fun of it and off course - security purpose. The video surveillance system set is available for customers all around the world and will be shipped via UPS worldwide express.

Labels: Chemical Engineer, Chemical Plant, Equipments

posted by Kipas Repair JB @ 8:44 PM,

,

![]()

Engineering Award

Monday, November 19, 2007

Would it be nice to be awarded handsomely for our good and brilliant effort? Would it be wonderful to be recognized by our peers and professionals from the same field? Have you been awarded for something before?

During my undergraduate studies, I was awarded “BP Computing Award 1998,

Few years after that, I’m a member (research officer and master student) of Chemical Reaction Engineering Group (CREG), a research group in Universiti Teknologi

Maybe you want to share some of your awards? Recognitions?

Other “Engineering Award” story occurred recently:

Continue reading HERE.

Labels: Chemical Engineer, Chemical Engineering, News

posted by Kipas Repair JB @ 11:01 PM,

,

![]()

Terrifying Forklift Accident

Sunday, November 18, 2007

Does your workplace have a forklift? If yes, you better be extra careful. My workplace have a lot of forklifts. We need those forklift to carry our drums, heavier goods and equipments (motor/pump/spare parts etc). A forklift do not have the speed equivalent to a car, but it can be deadly because of its mass and sometimes human carelessness.

A forklift accident recently took place in Hampshire industrial estate, United Kingdom. A lorry driver was crushed to death by a forklift truck in a horror accident. The unlucky man, aged in his twenties, had driven his lorry to Budds Lane in Romsey to deliver sheet metal to the firm Wessex Medical Equipment. It is believed he was hit by a green Mitsubishi forklift truck while he was standing at the back of his lorry and suffered serious injuries. Continue read the full news...

Morale of the story: Be careful wherever you are. Death can happen anytime anywhere even though we're perfectly healthy person.

posted by Kipas Repair JB @ 12:30 PM,

,

![]()

FROM THE CHEMICAL ENGINEER’S WIFE Part II

Wednesday, November 14, 2007

Therefore, with a heavy heart, I filled the form to enroll in the PhD program in my own faculty. It was not hard for me to choose my supervisor because I choose a person that I have worked with before for my Masters dissertation. I know his personality and he knows mine. We clicked. However, at that particular time, my supervisor has ran out of research grant money and has already completed all his existing research. Therefore, I was assigned to choose my own topic. I was lost for a while…but not for long. I reflected on what I want to do in the future and where will I be positioned in the faculty. I am supposed to be specializing in ‘separation method’ in chemical engineering because I have been told to join the Separation Group of the faculty. To be more specific, I chose ‘crystallization’ as my specialized area because nobody in the faculty has mastered it.

For those who are just embarking in pursuing their PhD, here are some tips on how to choose a PhD topic.

Some Tips on Choosing a PhD Topic

Labels: Chemical Engineering, Learning Curve, pH.D, Research, Study

posted by zura @ 4:51 PM,

,

![]()

Inside McDonalds Meat Processing Plant

Tuesday, November 13, 2007

Everybody enjoys having a happy hour meal at the most famous franchise fast food restaurant - "Mcdonalds" and that includes me. In fact, I just had a nice dinner with my family 2 days ago in Mcdonalds Jaya Jusco Johor Bahru. As I googled about processing plant, I found this very interesting short video on how the meat for their famous burgers are processed. It is amazing to learn about their hourly quality control (QC) to ensure that the meat is tasty and juicy before packing it. The cleanliness factor is also strictly taken into consideration. After neatly, safely and cleanly wrapping the boxes (which contains the meat), they're distributed throughout the States.

Labels: Control System, Equipments, Learning Curve, News, Process Parameters, Processing.

posted by Kipas Repair JB @ 11:16 PM,

,

![]()

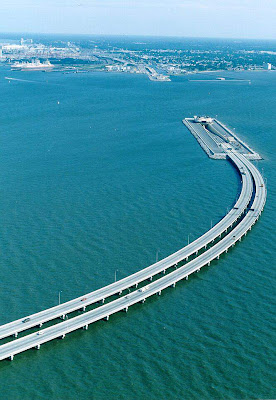

Photo of the Day, Half Bridge Half Tunnel

Sunday, November 11, 2007

This picture of the day is not directly related to chemical engineering stuff, but I admire and appreciate the engineering behind it. The bridge (or should it be called tunnel) goes under the water to allow movement of ships. In order to pass, this bridge is half under the water. You drive down in the water and then come out on the other side. Truly marvelous piece of engineering. This bridge is between Sweden and Denmark. This picture was taken from the Sweden side.

Labels: Picture of the day

posted by Kipas Repair JB @ 7:02 PM,

,

![]()

Oil and Gas - Global Refining Updates

I apologized for not updating this blog for a week. I'm been pretty busy the past few days. By the way, I received an email last week about being constantly updated with the global refining industry and it's associated rapid transformation. It's very informative and good reference if you're in the oil and gas arena. This is a paid subscription and you need to ask from their expert for more information regarding the content or subscription. Check it out. Following is part of the email that they sent to me. Dear Energy Industry Colleague, How much of new refining capacity will actually materialize? Hart Energy Consulting's World Refining & Fuels Service provides a single reference source on crude supply and quality, regional petroleum product demand and refining capacity and configuration trends; all provided on five global regions. SUBSCRIBE TODAY AND KEEP YOUR COMPANY AHEAD OF THE CURVE! For more information about the 2008 upgrades to the outlook, including questions about price and ordering, contact one of our experts or simply reply to this email: Frederick L. Potter Terry Higgins

World petroleum product markets are rapidly transforming. Rising crude prices, strong demand for cleaner fuels, and increasing pressure on refining capacities, make strategic planning for the next decade challenging.

What will be the role of biofuels and alternative fuels in the marketplace?

How will petroleum demand increase and which regions will provide the supply?

This expanded outlook includes the following new sections and analysis:

The Outlook is available in many forms to best suit your individual information needs: from a 500+ page hard copy report to a CD and full online access to the analysis, the data comes with 24/7 export support from our knowledgeable staff for on-site presentations and discussions.

1-703-891-4801

fpotter@hartenergy.com

1-703-891-4815

thiggins@hartenergy.com

Labels: Learning Curve, Magazine, News, Oil and Gas, Research, Review, Study

posted by Kipas Repair JB @ 4:04 PM,

,

![]()

300 , Design Project 2, 5S, NPSH, Pump - Rambling!!!

Sunday, November 04, 2007

I did not realize that the previous post about "Dipping Tape and Measuring Oil Tonnage" was my post number 300. That makes this current post that you're reading - number 301 in this Chemical Engineering World blog. Wow, it has been about 1 year and 3 months since I began blogging about my working experiences. I never expected , thought or dreamed this blog can be like what it is today. I never imagined to have more than 250 subscribers (at this moment and growing) for a technical chemical engineering blog. Thanks for your support.

This coming days will be a very hectic one for me. Tonnes of jobs and projects are waiting for me at work. We are going to have some minor 9 hours plant maintenance job. That job must be carefully coordinated in order to reach its objective - which is to improve the vacuum system in our plant process. I also have my plant monthly reports to complete and that is not easy as it need us to really focus and concentrate.

At the same time, the final year design project 2 file number 2 just arrived last Friday from a local university for me to read, digest, check, evaluate and give marks. I'm not sure when I can finish reading the design project report, but I was ordered to complete and email the marks by the end of this week... Well, I got to rush for that as well.

Oh yes... I almost forgot that I also need to conduct a 5S training for my plant operators. Maybe I'll arrange that on Tuesday afternoon.

Yesterday, on Saturday, I attended a very brilliant 3 hours training regarding pump. The training was conducted by one of our very experience and knowledgeable superior. From the training I discovered various types of pumps with various applications. We also did some real practice on how to calculate the Net Positive Suction Head (NPSH), based on our plant condition and situation. This was more advance from the basic NPSH that we learned in university. Furthermore, at university, we only know the theory, but this time, we experience and appreciate the NPSH knowledge... of course after we faced all the pump problems in the plant. We did learned other stuffs on why the pump trips, cavitate, air lock etc and it's relationship with the pump curve.

training was conducted by one of our very experience and knowledgeable superior. From the training I discovered various types of pumps with various applications. We also did some real practice on how to calculate the Net Positive Suction Head (NPSH), based on our plant condition and situation. This was more advance from the basic NPSH that we learned in university. Furthermore, at university, we only know the theory, but this time, we experience and appreciate the NPSH knowledge... of course after we faced all the pump problems in the plant. We did learned other stuffs on why the pump trips, cavitate, air lock etc and it's relationship with the pump curve.

Lately, I also received few emails asking me some favours on various issues and also asked for some advice/assistance. I'm trying my best to entertain those request, but occasionally, lately, I'm too busy. I hope you can understand my situation. I'll try my very best to get back to some of you. I'm also struggling and fighting with time to keep this blog updated with fresh feed and content for you to read. That's why I really appreciate anybody who is willing to provide one or two post (or more... which is good) so that we can have this blog updated more frequently. If you have anything to share, it can be from your own experience or some new stuff that you learn or know, you're welcome to email it to me. If it suite this blog, why should I not post it in this blog for you?!!

I also have some post which I did mentioned to elaborate more. I'll continue them soon. Just bare with me for a while. Some of you have personally asked the continuation of those post. Sorry for the delay mate...

Labels: Chemical Engineer, Jobs, Pump, Study, Training

posted by Kipas Repair JB @ 11:26 PM,

,

![]()

Dipping Tape and Measuring Oil Tonnage

Friday, November 02, 2007

In oil industry or oil plant, there are a lot of oil storage tanks available. It is vital for the oil company to know their daily oil stock simply because they are in the oil business. Therefore, they need to measure the oil volume and further work out its tonnage. They need to know the exact volume of oil and to do that there are various methods. One of the traditional method is by using a dipping tape.

What is a dipping tape? Sorry, I could not find a suitable and proper definition for it. My own definition would be a tape made of from stainless steel (can be other material as well) and has some sort of calibration along it (up to 15m, or 20m, it depends on your tank height) and it's used to measure the ullage in a storage tank (filled with oil/liquid). Does anybody have a suitable definition of dipping tape?

definition would be a tape made of from stainless steel (can be other material as well) and has some sort of calibration along it (up to 15m, or 20m, it depends on your tank height) and it's used to measure the ullage in a storage tank (filled with oil/liquid). Does anybody have a suitable definition of dipping tape?

I guess the next question from you will be: What is ullage?

The amount which a tank or vessel lacks of being full.

is the empty space present when a shipping container is not full.

The space in a tank not occupied by its contents. Used as a measure of storage space still available.

I hope the ullage definition would give you some idea on the concept.

For each storage tank, there'll be some sort of calibration table. From it, we can know what is the volume of oil at certain height. The tank height is also recorded in the calibration table. So, in order to know the volume of oil, we substract the tank height from the ullage (which we get from the dipping tape measurement), and we shall get the oil level height. From there, we can already get the volume of oil and work out the tonnage (with the temperature reading available).

Labels: Equipments, Oil and Fats, Oil and Gas

posted by Kipas Repair JB @ 12:00 AM,

,

![]()

The Author

I’m Zaki. I used to be a project, process and chemical engineer. Few years ago I successfully became a Chartered Engineer (IChemE) and Professional Engineer (BEM). I'm now employed as a chemical engineering educator/researcher/consultant. Hope you like reading my blog. I welcome any feedback from you. My email: zaki.yz[alias]gmail.com. TQ!