Flood Indirect Impact

Thursday, December 28, 2006

These are among the reasons why we are having CPO shortage!!! This happen in Segamat. In Kota Tinggi, about the same thing happen. The CPO tanker is already trapped in the fierce flood.

These are among the reasons why we are having CPO shortage!!! This happen in Segamat. In Kota Tinggi, about the same thing happen. The CPO tanker is already trapped in the fierce flood.

As an indirect result from this, my plant is forced to have a shutdown this 31st December 2006, Sunday. And guess what...That is a public holiday here in Malaysia because of the Haj Celebration and also the next day is the New Year!!! I have to work on that public holidays!!!

posted by Kipas Repair JB @ 10:47 PM,

,

![]()

Heavy Rain & Flood Impact To The Industry

Tuesday, December 26, 2006

It's still raining today. The rain keeps on pouring, heavily. The state/country is currently hit with one of the worse flood in history. Luckily my house and the surrounding area is not flooding. However, it gave a significant impact to my work. Not just when I go or return back from work, water clogging (minor flood), very bad traffic jammed, a lots of hole on the road, some damage to vehicles etc; it also force us (my company) to be prepared for a plant shutdown, simply becausethe crude palm oil (CPO) supply shortage.

It's still raining today. The rain keeps on pouring, heavily. The state/country is currently hit with one of the worse flood in history. Luckily my house and the surrounding area is not flooding. However, it gave a significant impact to my work. Not just when I go or return back from work, water clogging (minor flood), very bad traffic jammed, a lots of hole on the road, some damage to vehicles etc; it also force us (my company) to be prepared for a plant shutdown, simply becausethe crude palm oil (CPO) supply shortage.

We never expected such scenario to occur. Due to heavy rain, a lot of palm oil plantations was badly affected by the flood. Hundreds of workers associated to palm oil harvesting and milling could not go to work. CPO Tanker could not reach us because the road structure collapsed. We have a serius shortage of CPO. Most of our CPO tanks in the factory are empty. If the CPO run out, we have to stop the plant!!! We cannot blindly and easily stop the plant just like that. Therefore, we have to take the opportunity to perform any maintenance work. That's why now I'm quite busy alongside with my colleague preparing for the shutdown. I also have to carry the umbrella everywhere...

For more pictures showing the floods, you can click at my personal blog here.

posted by Kipas Repair JB @ 11:06 PM,

,

![]()

100th Posts in Chem-Eng World talks about Chlorophyll

Friday, December 22, 2006

I can't believed that it's already my 100 posts inside this blog within a space of 5 months. Well, I hope i can continue posting some good chemical engineering stuff.

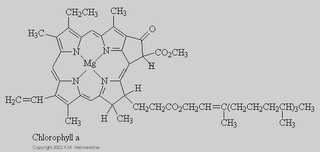

Few days ago, I have a meeting with a bleaching earth supplier, Taiko Clay. We have some technical discussion. I found that the discussion was very interesting and getting very technical as well. One of the interesting point that caught my attention was chlorophyll, which is always associated with plants. Chloropyll is also one of the impurities inside the crude palm oil (CPO). Before this i never know the chemical formula and structure of chlorophyll. I also did not know there are various types / forms of chlorophyll: ie. chloropyll a; b etc.I did not know that there is magnesium inside chlorophyll!!!

Therefore, I would like to share some piece of info that I picked up that day.

chlorophyll a (′klör·ə′fil ′ā)

C55H72O5N4Mg A magnesium chelate of dihydroporphyrin that is esterified with phytol and has a cyclopentanone ring; occurs in all higher plants and algae.

chlorophyll b (′klör·ə′fil ′bē)

C55H70O6N4Mg An ester similar to chlorophyll a but with a CHO substituted for a CH3; occurs in small amounts in all green plants and algae.

Read more about chlorophyll from wikipedia

Read more about chlorophyll from Answers.com

posted by Kipas Repair JB @ 10:28 PM,

,

![]()

35cm of Rain in Just A Day

Wednesday, December 20, 2006

This was the chronology of what happened to me on my way to work yesterday... JOHOR BARU: Continuous rain over the past 24 hours caused rivers to burst their banks, spilling water into streets and villages, and bringing the state to a virtual standstill.

0715 Hrs - Began driving from home to go to work

0900 Hrs - I'm stuck in Kempas (usually at normal day, I can reach here at 0730 Hrs)

0940 Hrs - I'm stuck in PLUS Highway exit to Pasir Gudang Highway (usually at normal day, I can reach here at 0740 Hrs)

1015 - 1250 Hrs - I'm stucked in Pasir Gudang Highway (usually I can reached my work place at 0800 Hrs; but now, it was already extraordinarily extremely very late!!!)

1300 Hrs - I managed to escape from the terrible jam and head back to my house. The flood was really worse. Rain was very heavy. So, I was forced not too go to work by nature!!!

Following is the news regarding the terrible flood occured that i Adopted from http://www.thestar.com.my

An estimated 9,000 people were forced to leave their homes following what has been regarded as the state’s highest rainfall in 100 years.

Sungai Segamat in Segamat, Sungai Skudai in Johor Baru and Sungai Mengkibol in Kluang were among five rivers whose waters overflowed.

At press time, 26 main roads were closed to traffic and nine cases of landslide had occurred.

So far, there has been no fatality because rescue teams managed to get the people to higher ground.

Mentri Besar Datuk Abdul Ghani Othman warned Johoreans to prepare for the worst as heavy rain was expected to continue until Friday.

|

SEEKING REFUGE: Flood victims from Kampung Laut and Kampung SK in Skudai taking shelter at SJK(C) Pu Tze in Skudai after being evacuated. |

Malacca was also not spared. Close to 200 people were evacuated in Jasin district, while a bridge in Durian Tunggal town had to be closed because the river overflowed.

As of 5pm yesterday, more than 3,700 people who vacated their houses in Johor Baru had been placed in 13 relief centres.

Johor Baru (North) OCPD Asst Comm Ruslan Hassan advised the people not to return home until the authorities give the all-clear.

“We had to rescue 29 people stranded on rooftops. These people ignored the danger and went home to salvage their stuff, but the water rose too fast,” said ACP Ruslan.

|

LOOMING DANGER: A landslide which occurred along Jalan Kolam Air has caused the wall surrounding this house close to collapse. |

In Muar, more than 1,600 people were moved to nine relief centres. Flooded areas included Lenga, Pagoh, Gersik, Sagil, Bakri, Bukit Gambir, Tangkak, Sungai Mati, Kampung Batu 23, Gombang, Felda Maokil, Kampung Paya Redan, Kampung Paya Lempah, Kampung Paya Pulai and Kampung Teratai.

Muar police chief Asst Comm Mohd Nizar Mohd Ali reminded parents to keep a tight rein on their children and not let them play in the flood waters.

In Kluang, close to 3,000 people from 20 villages fled their homes, while 540 residents from Parit Raja in Batu Pahat and 170 people from Pontian had to seek shelter at relief centres.

|

ROADS UNDER WATER: Pedestrians walking through a flooded road near Wisma Persekutuan in Johor Baru yesterday. |

Johor Drainage and Irrigation Department (DID) acting director Chong Chee Han said water in the Sembrong Dam and Machap Dam was at a high level, but the DID could not release the water.

“If water is channelled into the rivers, the low-lying areas of Parit Raja and Simpang Rengam could be inundated,” said Chong, who attributed the high rainfall to the North-East Monsoon.

Meanwhile, the Army has put seven brigades and 20 boats on standby.

An Army spokesman said the military would send in a Nuri helicopter for rescue operations if necessary.

posted by Kipas Repair JB @ 11:07 PM,

,

![]()

Visitors to Plant

Sunday, December 17, 2006

Last week, my scheduled was so tight. In a space of 2 days, I have to standby and wait for three different visitors who happen to be very important to the company. I have to ensure the plant is in extra clean and in good condition. Well, although the day and date is known, the exact time of visit to the control room and plant is unknown. There was no indication of what time they are coming. Therefore, I have to wait and do what ever work i can do in the control room. Well, that's fine, at least i can do a little bit of work using the PC available in the control room.

The first group of visitors were from Australia and they are oil traders. The second group was from the Iran ministry of health. The third group was from the ministry of Sabah. As for me, when all these visitors came, I have to explain briefly our process on how we convert crude palm (CPO) oil to refined bleached deodorized palm oil (RBDPO).

posted by Kipas Repair JB @ 7:57 PM,

,

![]()

Some Comparisons of My Jobs

Monday, December 11, 2006

Since I graduated in 1999, I have been in three different chemical engineering fields. The first is Reaction Engineering, Chemical Engineering Research (Aug 1999 - Dec 2002) which I gained my Masters Degree from. The second is Chemical Engineering in Oil and Gas Industry (Jan 2003 - June 2005) and at present, Chemical Engineering in Oil and Fats Industry (June 2005 - present)...

If asked...which one I enjoyed the most:

Chemical Engineering in Oil and Gas Industry - I tasted and experienced a lot of interesting stuff

If asked...which one I learned a lot (really practicing chemical engineering fundamental):

Chemical Engineering in Oil and Fats Industry - I practiced a lot of Unit Operations

If asked...which one is more relaxing:

Chemical Engineering in Oil and Gas Industry - Maybe because it's a service company...

If asked...which one is more challenging:

Chemical Engineering in Oil and Fats Industry &

Chemical Engineering in Oil and Gas Industry - Both have different angles of challenge

If asked...which one I prefer to be in now:

Chemical Engineering Research - I love doing research + publication

If asked...which one I make the most money (salary + allowances):

Chemical Engineering in Oil and Gas Industry - Undeniably the wealthiest field

If asked...which one really consumed a lot of my time:

Chemical Engineering in Oil and Fats Industry - I just work, work, work till late ....

If asked...which one I have more downlines:

Chemical Engineering in Oil and Fats Industry - I have skillful operators to help running the plant

If asked...which one I felt more pride:

Chemical Engineering in Oil and Gas Industry - Well, it's a proud feeling being in this industry

If asked...which one allows me to travel more:

Chemical Engineering in Oil and Gas Industry - Went overseas as well as offshore...from a four wheel drive Pajero to a Sikhorsky 76 chopper....from an antic mercedes to a boeing 737 aircraft....from Singaporean dollar to Rupiah....

If asked...which one allows me to do more publications:

Chemical Engineering Research - I published quite a number of papers and journal with my supervisor

If asked...which one gives me more exposure:

Chemical Engineering in Oil and Gas Industry - Living in an oil rig platform is fun, interesting and makes me eat all the time....provided if you don't stay there 4 weeks in a row....

The above points are just my opinion and purely what I feel from my experiences. For your information, I did my full time research in University Teknologi Malaysia. I worked in a service company which deal in oil and gas as a chemical engineer cum project engineer. Latest, I am a process engineer taking care of a physical refinery plant processing mostly palm oil and sometimes some lauric oil. I think I'll continue this subject later....I think it might be interesting....to elaborate further....

Labels: Learning Curve

posted by Kipas Repair JB @ 10:37 PM,

,

![]()

Biofuels: new fuels from bacteria

Friday, December 08, 2006

Another interesting article about biofuel / biodiesel which I read from EngineerLive.com. Well, there'll be a lot more to be discovered about biofuel as well as huge area to explore...The following article is about biofuel from bacteria....

‘Microdiesel’ can also use readily available bulk plant materials or even recycled waste paper if engineering of the production strain is more advanced

A breakthrough in the production of biofuels has been developed by scientists in Germany. Research published in the September 2006 issue of Microbiology, a Society for General Microbiology journal, describes how specially engineered bacteria could be used to make fuel completely from food crops.

“Biodiesel is an alternative energy source and a substitute for petroleum-based diesel fuel,” explains Professor Steinbüchel of the Westfälische Wilhelms-Universität in Münster. “A growing number of countries are already making biodiesel on a large scale, but the current method of production is still costly”.

“Biodiesel production depends on plant oils obtained from seeds of oilseed crops like rapeseed or soy”, explains Professor Steinbüchel. “However, production of plant oils has a huge demand of acreage which is one of the main factors limiting a more widespread use of biodiesel today. In addition, biodiesel production must compete with the production of food, which also raises some ethical concerns”.

Microdiesel, as the scientists have named it, is different from other production methods because it not only uses the same plant oils, but can also use readily available bulk plant materials or even recycled waste paper if engineering of the production strain is more advanced.

Also, it does not rely on the addition of toxic methanol from fossil resources, like many other biodiesels. The bacteria developed for use in the Microdiesel process make their own ethanol instead. This could help to keep the costs of production down and means that the fuel is made from 100 per cent renewable resources.

“Due to the much lower price of the raw materials used in this new process, as well as their great abundance, the Microdiesel process can result in a more widespread production of biofuel at a competitive price in the future”, says Professor Steinbüchel.

There is a growing number of fuels used in cars and homes that are produced with the help of microbes. UK ministers are considering doubling the targets for the amount of biofuels sold in Britain by 2015.

The Society for General Microbiology disseminates current research findings in microbiology in its four journals. The SGM is the largest microbiology society in Europe, and has over 5,500 members worldwide. The Society provides a common meeting ground for scientists working in research and in fields with applications in microbiology including medicine, veterinary medicine, pharmaceuticals, industry, agriculture, food, the environment and education.

posted by Kipas Repair JB @ 10:22 PM,

,

![]()

OSEA 2006 is now in Singapore

Wednesday, December 06, 2006

OSEA2006 is now on. See you at Suntec Singapore! To register for the event or if you had pre-registered but did not receive your confirmation email or number, please bring along your business card and register at Suntec Singapore (Level 4) at Halls 402 & 403 during the show days. Unfortunately I could not come because I'm so attached with the work in my plant. Perhaps the next OSEA I will attend. If anybody have attended this very big event, why not tell something about it...Few details about OSEA2006 below...

Exhibition & International Conference

Date: 5-8 December 2006 (Tuesday – Friday)

Venue: Suntec Singapore

Opening Hours: 1030 hrs – 1800 hrs

| The Event | ||

OSEA was established three decades ago to be the industry event for Asia’s oil and gas industry. This international event brings together 10,000 industry professionals to tackle the pertinent concerns of the Asian oil and gas industry, from its technological front to changing market trends and expectations to new business potential and the running of its daily operations. The international character and regional audience of OSEA present unparalleled marketing, education and networking opportunities. Join this event to take on the challenges of today’s global energy industry and tomorrow’s borderless markets. Flashback to OSEA2004: 9,109 Trade Visitors from 60 countries 896 Exhibiting Companies from 48 Countries 5 National Oil Organisations: BPMIGAS, Kuwait Petroleum Corporation, Philippine National Oil Company, Singapore Petroleum Company, Timor Leste JDA. 48 International Press Attendees include: ABB, Aker Kvaerner, Amerada Hess, Amoseas, Atwood Oceanic, Baker Hughes, BJ Services, Brunei Shell, Cairn Energy, Carigali-Triton, Ceylon Petroleum Corp, Chevron Offshore, China Offshore, China Oilfield, Chiyoda, CNOOC, Con Son JOC, Conoco Phillips, Cooper Cameron, Crest Petroleum, CS Mutiara, Cuu Long JOC, Devon Energy, Dialog, Diamond Offshore, Ensco, EPIC Energy, ExxonMobil, Federal, FMC, Foster Wheeler, Frigstad, Fugro, Gazprom, Halliburton, Iran Marine, Jay McDermott, Japex, JGC, Kellogg Brown & Root, Keppel, Shell, KNOC, MedcoEnergi, Murphy Sarawak, Naftogas, Oil India, Pearl energy, Petra Fabricators, Petronas, Petrovietnam, Premier Oil , PTTEP, Rainhill, Saipem, Saudi Aramco, Schlumberger, Smedvig, Stolt Offshore, Technip, Titan Group, Total, Transocean, Unocal, Vico Indonesia, Weatherford, Woodside, Worley, Yantai Raffles ..and many others Check out the conference program here

|

posted by Kipas Repair JB @ 9:03 PM,

,

![]()

Found Abnormality, Take Immediate Action

Monday, December 04, 2006

Just now in the afternoon, I walked pass my plant and i saw the suction pipe to the 37.5kW pump delivering water to one of my cooling tower is vibrating badly. I have a closer look to inspect it. I saw water dripping from it and i felt that the pipe is already very thin. The pipe has experienced a bad errosion from the acidic water flowing through it. I immedietly called my plant operator and asked them to switch pump, and called maintenance team to replace piece of the pipe which is already beginning to break down into pieces. After issuing a job order to rectify the situation, maintenance team prepared their stuff and immedietly came to the site and replaced the piece of pipe which is badly fractured. Within 2 hours from the time i informed my operator, everything was sorted out smoothly and the suction pipe to the pump has is ready to resume operation.

Morals:

1. When you see some abnormality(s), immedietly report or take action.

2. Anything that might affect your plan process/system, must be immedietly rectified.

3. Never delay any abnormality or problem - you might forget about it, and after a few hours of taking action, it might be late!

4. Follow up! Do not take any instruction you gave for granted. Maybe your downline delay it. So, create some urgency in the instruction depending on the situation.

5. I cannot think for some more....I'm exhausted....

posted by Kipas Repair JB @ 8:46 PM,

,

![]()

Understanding Plant Tips

Sunday, December 03, 2006

For you chemical engineers out there who happen to become a production executive or a process engineer (or what ever position it is named after) who has the responsibility of taking care of the plant, here are some useful tips to ensure you understand the plant as fast possible.

1. Learn all the piping system in your plant. With this you can have better comprehension on the plant process.

2. Learn how to start and stop the plant. This is always the important thing to know. If the plant is having problem - you stop it. If problem solved - start it back.

3. Don't be embarased to ask the supervisors or plant operators about the plant. In most plant, they have been operating the plant for a lot of years. They have tremendous experience on operating the plant and some trouble shooting. You can asked about the plant and asked from a lot of them. Therefore, you'll get more informations from a lot of operators, and most of the time the info that you need will be common.

I hope those tips can be useful. It is useful for me. I'm still learning my plant as well. It is a continuous process of learning. Furthermore, the plant that I'm handling is very big (size and capacity!!!). I would like to thank my senior collegues (2 of them) who gave me those useful tips. I appreciate their kindness of passing me the knowledge, informations, skills and tips....Thanks as well to my supervisors and operators for their hardwork and duty in running the plant. Not to mention all the maintenance, electrical, instrumentation team. I hope my plant will continue to run smoothly...

posted by Kipas Repair JB @ 11:45 AM,

,

![]()

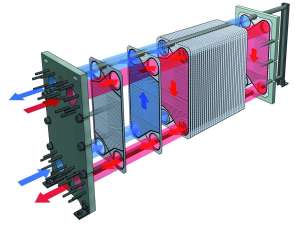

Plant Performance - Heat Exchangers Dillema

Wednesday, November 29, 2006

I have been looking and concentrating to improve my plant performance. Sometimes, it's difficult to get the desired oil quality and the management will questions this. Sometimes, I cannot produce the target throughput that I am suppose to deliver. Some of the prime reason is just because of inefficient heating in the plant, which means my heat exchangers are not working effectively. Therefore, i cannot get the heat that i wanted which directly affects the oil product quality. Now, my major task (together with the others) is improving all the heat exchangers so that they are properly maintained. I need to have extra fresh plates for plate heat exchanger so that we can immedietly have it for back up. I also need to add some more "cleaning in progress" line, to clean the heat exchanger on-line. Well, this is among the challenge that I have to face. So, in the mean time, I have to work with some of the less effective heat exchangers. If the heat exchangers are not ok, the plant will consume more steam and natural gas/fuel apart of not getting the quality. Anybody facing the same problem....?

posted by Kipas Repair JB @ 9:23 PM,

,

![]()

MAHA EXPO 2006 - Great Agricultural Event!!!

Sunday, November 26, 2006

Today, I went to MAHA EXPO 2006 (Malaysia Agriculture Holticulture Agrotourism) which was located in MARDI (Malaysian Agricultural Research and Development Institute), Serdang, Selangor, Malaysia. Well, I went there not for official business, but rather gathering some information and adding up some new and fresh knowledge inside my brain cell about the agro-bio industry. There were thousands of people pouring into the exhibition which is the largest in Asia. It was very difficult for me to walk my way through the exhibition booth. I learn some new technology on growing some crops, got myself some info about the available loans and supports for interested parties who want to developt the agricultural business, and lots of more informations. It's basically a growing exciting sector to venture. On overall, i can say that MOHA 2006 is a very brilliant event conducted by the Malaysia's Ministry of Agriculture (MOA), but it definitely need to improve few things such as handling such a huge gigantic visitors and directions etc.

Today, I went to MAHA EXPO 2006 (Malaysia Agriculture Holticulture Agrotourism) which was located in MARDI (Malaysian Agricultural Research and Development Institute), Serdang, Selangor, Malaysia. Well, I went there not for official business, but rather gathering some information and adding up some new and fresh knowledge inside my brain cell about the agro-bio industry. There were thousands of people pouring into the exhibition which is the largest in Asia. It was very difficult for me to walk my way through the exhibition booth. I learn some new technology on growing some crops, got myself some info about the available loans and supports for interested parties who want to developt the agricultural business, and lots of more informations. It's basically a growing exciting sector to venture. On overall, i can say that MOHA 2006 is a very brilliant event conducted by the Malaysia's Ministry of Agriculture (MOA), but it definitely need to improve few things such as handling such a huge gigantic visitors and directions etc.

Subscribe to this blog to get updated with various chemical engineering and personal experience info/sharing...subscribe link on the side bar or at the bottom of this page

posted by Kipas Repair JB @ 2:21 AM,

,

![]()

Schmidt-Bretten Plate Heat Exchanger

Wednesday, November 22, 2006

I used a lot of plate heat exhangers in my plant and most of them are manufactured by Schmidt-Bretten. The model/type of plate heat exchanger that i used is Sigma 64. Just like the one that you can see on my previous post, but that one is fouling badly. You can see the pieces of hard gum and scale etc ugly stuff....

I used a lot of plate heat exhangers in my plant and most of them are manufactured by Schmidt-Bretten. The model/type of plate heat exchanger that i used is Sigma 64. Just like the one that you can see on my previous post, but that one is fouling badly. You can see the pieces of hard gum and scale etc ugly stuff....

I'm having a tough time gathering informations and

inventory of my spare heat exchanger plates. I need to back up my plates so that i can dismantle a heat exchanger and replace them immedietly with the spare plates come with gasket. This is very important to ensure production smoothness. Well, there's a lot to tell about a small topic of heat exchanger. We do not get this in university and text book. We get most of this from experience.

Following are some information that i took from Schmidt-Bretten site.

The main advantages of plate heat exchangers are

* High heat transfer coefficient with low surface areas.

* Compact design, does not need much space.

* Small temperature differences are possible between the fluids.

* High versatility, the design allows for fast and easy rearranging of the plates as operating or process conditions change.

* Movable pressure plates allow easy access to the plates for cleaning.

* Low investment costs.

* High corrosion resistance.

* A plate exchanger contains only low quantities of fluids.

* Material for plates and gaskets is chosen according to end use.

* Easy-to-service.

Read more from Schmidt-Bretten Link Here

Subscribe to this blog to get updated with various chemical engineering experience info/sharing...subscribe link on the side bar

Labels: Heat Exchanger

posted by Kipas Repair JB @ 10:30 PM,

,

![]()

Dismantling Plate Heat Exchanger

Tuesday, November 21, 2006

Following are the photos of plate heat exchanger (PHE) that we recently decide to open up because we cannot get good heat exchange and desired temperature. The PHE has been in operation for about 2 years already. We can see gum from crude palm oil (CPO) sticking on the outer part of the plates which create fouling on the PHE. All together there are 115 plates on this PHE. Now, we are dismantling it too clean the plates.

The black hardened gum from CPO is found sticking on the plates. Some of the pieces of hardened gum have been removed, and we can slightly see the plates. Can you see it?

The black hardened gum from CPO is found sticking on the plates. Some of the pieces of hardened gum have been removed, and we can slightly see the plates. Can you see it?While dismantling this heat exchanger, we found some other problems. Later I shall discuss about it.

Labels: Heat Exchanger

posted by Kipas Repair JB @ 11:18 PM,

,

![]()

Vacuum System Failure Rejection

Thursday, November 16, 2006

Another thing that I don't like while running a plant is having a down time. I hated it most when oil rejection occurs. Rejection will happen for various reasons. One of it which occasionally happen is the pressure vaccum drop. Oohh... when this happen, the oil Free fatty acid (FFA) content or oil colour will be out of spec. And this will force my plant operators to reject the oil to their respective crude oil tank. I'm still learning and exploring as well about the vacuum system in my plant. I need to maintain the dirty cooling tower pressure and temperature within the desired range. If the cooling water temperature slightly increase, it can affect the vacuum system and resulted in vacuum drop. It's ok if i know and can explain the why the down time or rejection happen. I hate it when i don't know the reason. It makes my life a little bit difficult explaining and answering all sorts of questions being bombarded at me just because i cannot meet the daily production target. Well, this makes me want to really make sure that all the processing parameters are within range and control. Need to prevent any plant breakdown and downtime from happening....

Labels: Problem

posted by Kipas Repair JB @ 11:44 PM,

,

![]()

Throughput Versus Quality - Heat Exchanger Dilemma

Wednesday, November 15, 2006

I'm in a deep headache now. I have to deliver a throughput of 3000 MT/day. Now, one of the twin plant is having a small problem. My plate heat exchanger is suddenly not giving the sort of heat transfer that i wanted. As a result the quality which will be achieved by having high temperature could not be obtained. I have to lower the flow rate of oil passing through the heat exchanger so that better heat exchange can take place. The heat exchanger can cope with 40 m3/hr flowrate that i normally run, but the temperature of 230 could not be achieved. So, i have to lower it down to about 34 - 36 m3/hr. And around this time, the shipment is very tight which means i have to deliver processed oil which always must be above 3000 Mt/day. The heat exchanger must be stopped and cleaned. I must replaced it with another spare heat exchanger. The problem is, my spare heat exchanger is also having some other problems. Ohh goshhh....

posted by Kipas Repair JB @ 8:49 PM,

,

![]()

Not A Chemical Engineer, But Performs Like One!!!

Monday, November 13, 2006

I worked in a physical refining plant and currently take care of a big plant. Before this, the plant is always taken care by two executives/engineers. Now, my senior colleague (we took care of the plant together), Mr Jomani is going to leave because he was awarded a very damn good offer from a foreign company. The payment is a lot too. I'm not really sure, but my guess is that he is going to be paid 4 times what he is earning in this company. What I want to highlight here is everything about him. And I'm going to take care of the plant alone now.

All this while he has been my senior, mentor, guru, collegue, etc....you name it.....He is very good in almost every technical aspect in the edible oil industry. He managed to take a very good care of the plant and has help improved the plant production capacity/upgrading from less than 2000 tonnes/day to about more than 3000 tonnes per day. He has been working in the present factory/plant for almost 13 years. And in the industry for almost 30 years....i guessed....

What impressed me most is his educational background. He is not a graduate. He does not have any certificate. He's only education is the high schoole/secondary school. He started to work in a factory not as an operator but as a cleaner (this is what i was told, i'm sorry if i'm wrong). During work, he saw plant operators operating the plant and became interested. He quitely learned and he became a plant operator. He was deligent and he was promoted to become shift leader and later supervisor. Soon, he was offered a better and more challenging job in the place where I'm working now as a production executive (a title where it is usually offered to graduate engineer). Later he forced himself to become a senior production executive. And now, he is going to be a very important person in the new company that he will work for.

How can he became like that? It's the attitute, hardwork, dedication, determination and most importantly the willingness to keep learning and learning. Although he was only a high school leaver, but he managed to become better that a practicing chemical engineer. He forced himself to converse in English. He did mentioned to me he took an intensive course to learn English. He practice and learn computer skills to do reports etc. He learn management skills etc. He learn all the neccesary technical stuff. He learned about pressure, temperature, flow rate, vessels, boilers, cooling towers, piping, PLC, control system, NPSH and hell lot more...all from his exposures and experiences. Huhh.....what a fantastic person he is....Later, i planned to intereview him. I hope i can do so, and published it inside here. All for us to benefit from it....

posted by Kipas Repair JB @ 8:12 PM,

,

![]()

Novel US ‘Super Boiler’

Sunday, November 12, 2006

As a person who uses the steam from boilers regularly, I found out about this article/news from the "engineerlive.com/european-process-engineer" newsletter. It's an interesting and very good innovation that I think i better share it with the rest of you. Those who operate or who'se close to boiler operation may found this interesting, i guess....

An Illinois-based organisation dedicated to research, development and training for the natural gas industry has developed a new industrial steam generation system that provides increased efficiency, reduced emissions and lower fuel costs.

Gas Technology Institute (GTI) has teamed with Cleaver-Brooks-a leader in packaged boilers for industrial, institutional, and commercial applications-to focus efforts on bringing technological advances to the marketplace.

Smaller footprint

Now in field demonstration at Specification Rubber Products in Alabama, the advanced

gas-fired boiler-dubbed the ‘super boiler’ by its sponsors-has shown significant performance improvements over alternative technologies.

In addition, the boiler has a 40percent smaller footprint and half the weight of conventional boilers.

Read more here http://www.engineerlive.com/european-process-engineer/16618/field-tests-begin-on-novel-us-super-boiler.thtml

posted by Kipas Repair JB @ 11:38 PM,

,

![]()

Determining if a pipe is running full or is at its sealing flowrate?

Saturday, November 11, 2006

How can one determine if a pipe is running full or is at its sealing flowrate?

The following equation gives a quick check to determine the sealing velocity for a pipe:

Q = 10.2 D^2.5

where:

Q is the liquid flowrate in gallons per minute

D is the pipe diameter in inches

If the current flowrate in the pipe is less than the value calculated for Q above, then the pipe is below its sealing flowrate or is said to be partially flooded. In order to calculate the velocity in this pipe you must use a set of flow area equation presented in Chemical Engineering magazine (March 1998, p. 129). The above equation is valid for liquid flow through a horizontal pipe.

Adopted from http://www.cheresources.com/chexpress/chexpress28.shtml

posted by Kipas Repair JB @ 7:47 PM,

,

![]()

Taking Care of a Physical Refinery Plant

The pass 2 weeks was a very tough for me at work. And it's not going to end. This is just the beginning. A major part of my job is to take care a very big physical refining plant, with a capacity of 3000MT/day running 24 hours for about 355 days a year together with a very experience senior production executive. Another major part of my job is to take care of quite a number of projects and utilitiy jobs inside the factory. This consume a lot of my time and as a result, my duty and time for plant is not much. I always depend on my senior colleague when it comes to the plant matter. I just started co-taking care of the plant with him for about 1.5 years now.

My worse night mare have come. My senior colleague was offered a very good job and position elsewhere. The payment is damn good too. And for that, I guess, I'm going to take care the plant alone. I really don't mine taking care of the plant if I have all the knowledge and skill to control and take care of the plant. The problem is that the knowledge and skill is still not sufficient for me to take care of the biggest physical refining plant in south johor alone. I need some assistance. Between last week and this coming week, I'm racing against time to learn as much as possible everything in detail about the plant from the senior production executive. It's a very big plant. It's a very fast plant. It's a very damn important plant. I cannot effort to make any mistake in delivering instruction to my subordinates or controling the plant. I have to be 24 hours alert of what's happening to the plant because the plant is running 24 hours.

This job might look simple for those who're already experience. But for me, I'm still considered new and fresh to this plant although I know and can understand the theoretical part of the plant.

Well, I have to face this challenge. I have no choice. There're not other people to fit in here. I'm going to face it...wish me luck..you guys...pray for me....God help me....

posted by Kipas Repair JB @ 5:27 PM,

,

![]()

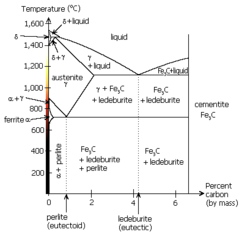

TYPES OF STEEL

Thursday, November 09, 2006

Iron ore pellets for the production of steel

Iron ore pellets for the production of steelLow Carbon Steel: It contains 0.2% carbon.

Uses: Sheets, wires, pipes.

Mild Carbon Steel: It contains 0.3% to 0.7% carbon.

Uses: Rails, boilers, plates, axles, structures.

High Carbon Steel: It contains 0.7% to 1.5% carbon.

Uses: Surgical instruments, razor blades, cutlery, spring.

STAINLESS STEEL

Uses: Car accessories, watch case, utensils, cutlery, pipes.

ALLOY STEEL

There are three types of alloy steel.

Mn-Steel: It contains 10%-18% Mn.

Uses: Rail tracks, armor plate, safe.

Si-Steel: It contains 1% to 5% Si.

Uses: Permanent magnet.

Ni-Steel: It contains 2% to 4% Ni.

Uses: Gear, shaft, cable.

Adopted from http://www.citycollegiate.com/IX_steeltypes.htm

Read more about interesting steel from Wikipedia HERE

posted by Kipas Repair JB @ 10:33 PM,

,

![]()

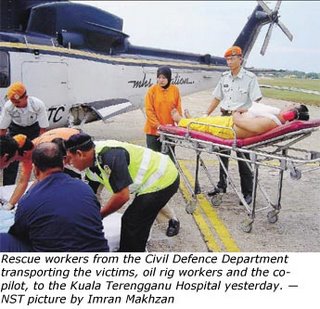

Helicopter Crash - Tapis B Offshore Platform

Tuesday, November 07, 2006

The helicopter crash at offshore Trengganu (while attempting to land at Tapis B Platform in a storm) last Sunday (5/11/2006) really caught my attention. It was a Super Puma helicopter which tranported 19 passengers + 2 pilots (The pilot did not survived). I still remember being on a Super Puma when i travelled offshore long time ago. I did not favour being inside a Super Puma. My friend, Tom, also prefers not to travel in it. We don't feel comfortable being in it. The control, maneuver and stability is the main reason. I rather choose to be in a Sikhorsky 60 or Sikhorsky 76. Well, that was long time ago. But the importance of the "Helicopter Under Water Escape Training" is really vital for this situation. It also reminded me that being in the oil and gas - offshore industry is fun, interesing, challenging and sometimes dangerous.

The helicopter crash at offshore Trengganu (while attempting to land at Tapis B Platform in a storm) last Sunday (5/11/2006) really caught my attention. It was a Super Puma helicopter which tranported 19 passengers + 2 pilots (The pilot did not survived). I still remember being on a Super Puma when i travelled offshore long time ago. I did not favour being inside a Super Puma. My friend, Tom, also prefers not to travel in it. We don't feel comfortable being in it. The control, maneuver and stability is the main reason. I rather choose to be in a Sikhorsky 60 or Sikhorsky 76. Well, that was long time ago. But the importance of the "Helicopter Under Water Escape Training" is really vital for this situation. It also reminded me that being in the oil and gas - offshore industry is fun, interesing, challenging and sometimes dangerous.

Read the news of the incident HERE. and also another one from VerticalReference.com

Read some news about it from Bernama.

Read news from NST.com

posted by Kipas Repair JB @ 9:09 PM,

,

![]()

OSEA 2006 Conference

GAS RECOVERY – THE GOOD, THE BAD & THE UGLY

GAS RECOVERY – THE GOOD, THE BAD & THE UGLY

Gas has always been difficult to handle when discovered, both on land and offshore. You can't put it in a barrel or a tank. You had to have a market and a pipeline. But not any more.

Not with the evolution of new technology such as conversion methods to liquefy the gas - GTL, LNG, methanol, or the development of approved CNG carriers. Putting such equipment onto FPSO-type vessels could be the solution to all the stranded gas around, not just in Asia, but around the globe wherever gas fields are found. Sometimes it might even be cheaper to pipe gas back offshore for compression, rather than run expensive pipelines around protected areas. This is a solution looking for a problem. The future is now.

Here's your chance to take a long-awaited look at the techniques and technologies available to recover stranded or uneconomical offshore gas reserves at the OSEA2006 Gas Recovery Conference!

Hear from the experts as they debate the pros and cons of various gas recovery methods at the Roundtable • Which method is likely to be the most expensive? • Most efficient in terms of total recovery? • Most difficult to install and maintain? • What are the relative weaknesses and strengths of the different systems? • What is the time scale for implementation of each? • To buy or to lease? What are the life span and long range economics?

Have all your burning questions answered at the interactive Q&A sessions!

PLUS! Don't miss out on the other two conferences focused on Upstream and Production technologies.

SCHEDULE-AT-A-GLANCE

Preview the Schedule-at-a-Glance, conference topics and speakers at www.osea-asia.com/Conference_Programme.htm

LIMITED SPEAKING OPPORTUNITIES

If you're still interested in presenting a paper at the conference, please email cs@sesallworld.com with your proposal.

CONFERENCE REGISTRATION

Visit www.osea-asia.com/registration.htm to secure your seat today or contact the Conference Team at Tel: +65 6233 8622,

Email: cs@sesallworld.com

Seats are filling up fast! Sign up for the OSEA2006 Conferences today to avoid disappoint.

CONNECT WITH MAJOR PLAYERS ACROSS THE OIL AND GAS VALUE CHAIN AT THE CONCURRENT OSEA2006 EXHIBITION

• View the hottest new technologies from over 800 companies, coming from more than 48 countries

• See pavilions from Australia, China, Germany, Italy, Norway, UK and USA

• Meet more than 10,000 industry and business professionals from over 60 countries

• Network with market leaders at the OSEA Networking Night and Golf Tournament

Click here to pre-register for the exhibition.

posted by Kipas Repair JB @ 8:42 PM,

,

![]()

Hot Water System Problem

Monday, November 06, 2006

Few weeks ago, our specialty chemical vendor from Nalco came and performed his routine water testing in one of the plant in my factory. He was testing the hot water tank system and found out that the water pH was below 6. The pH is supposed to be control at about 8. Other chemical parameters seems to ok and within normal range. So, he added some caustic solution into the hot water system to increase the pH. He also advised us to dispose half of the water inside the system and introduce fresh water. He gave me a copy of the report and told me the situation.

Few weeks ago, our specialty chemical vendor from Nalco came and performed his routine water testing in one of the plant in my factory. He was testing the hot water tank system and found out that the water pH was below 6. The pH is supposed to be control at about 8. Other chemical parameters seems to ok and within normal range. So, he added some caustic solution into the hot water system to increase the pH. He also advised us to dispose half of the water inside the system and introduce fresh water. He gave me a copy of the report and told me the situation.

Later, the same day, a supervisor from the above mentioned plant was instructed to flush/blowdown the water in the hot water system. As soon as he opened the final valve, a red hot colour water came out from the system. We were surprised with the colour of the water! My bos who saw the water colour immedietly thought a severe corrosion is taking place inside the system. I went to the site at observed, took some photos and took some sample as well.

From my previous experince, i know that, if corrosion really takes place, the iron which is heavier will sediment on the bottom of the sample bottle. I waited for one day and the next day, i found out that the water is still in the same state and colour. No changes can be observed from the colour. This is a very homogeneous solution and i believed that this is not corrosion. It was something else.

Later we realised that the red colour water is actually a product of a chemical reaction inside the hot water system. When the chemical vendor poured in some caustic solution to increase the pH, the solution actually reacted with some oil inside it. We are still not sure which type of oil (Lab test indication). But, this shows that one or more heat exchanger in the system is leaking.

So, second conclusion ---> One or more heat exchanger is leaking and therefore, the plant personel must detect which heat exchanger is leaking and isolate them.

posted by Kipas Repair JB @ 8:29 PM,

,

![]()

What is 'condensate lift'?

This is a term that is usually used to indicate how much pressure is required to 'lift' condensate from a steam trap or other device to it's destination at a condensate return line or condensate vessel.

The first image below shows a situation where a properly sized control valve is used on a steam heater. During nominal operation, the utility steam undergoes a nominal 10-25 psi pressure loss through the valve. For typical utility steam (150 psi or higher), this can leave a pressure at the steam trap exit that is often adequate to lift the condensate to it's destination. For example, if the steam losses 20 psi through the valve and another 15 psi through the heater and piping, that can leave up to 265 ft of head to push the condensate to the header. In this case, there's little need for a condensate pump.

On the other hand, if the control is too large, it will only be a few percent open during normal operation and the steam can undergo a pressure loss of 50-75 psi or even higher! In addition to supplying terrible control for the heater, it also reduces the available head for condensate lift. In this case, or if the steam supply pressure is relatively low, it may be necessary follow the steam trap with a separation vessel and a condensate pump to push the condensate to the return line.

Adopted from Cheresources.com Newsletter

posted by Kipas Repair JB @ 7:40 PM,

,

![]()

More Design of Experiment Infos

Today, I received some input/info from Mr. John Hunter (Son of William Hunter, one of the various Design of Experiment founder alongside with Mr George Box) . Thanks John for your input. Box-Hunter is one of the design of experiment (wikipedia version) technique widely used world wide apart from Response Surface Methodology (RSM).

I know these informations and links are very useful for those who deal a lot with experiments.

Quoted from John's input:

Here are some good sites with more information on design of experiments and articles on design of experiments including many from the Center of Quality and Productivity Improvement at the University of Wisconsin that was founded by William Hunter, my father and George Box (leaders in the field, in my biased opinion, but others opinions as well).

posted by Kipas Repair JB @ 8:34 PM,

,

![]()

Flow Measurement Products

Two weeks ago I went to a half a day Endress + Hauser Biodiesel Instrumentation Seminar. I learned more about their product range there. Here I attached some of the flow measurement range product from Endress + Hauser that can be used from various range of condition. Those are the coriolis flow meters which can provide very accurate reading. Study more about the company at http://www.endress.com/.

Study more about the flow meter products HERE.

Get the Endress Hauser magazine HERE.

Learn more about other products from Endress Hauser HERE.

posted by Kipas Repair JB @ 11:47 PM,

,

![]()

Turbine Regenerative Pump

What type of pump may be appropriate for a liquid near saturation, a low flow rate, and very limited NPSHa (net positive suction head available)?

This application is nearly perfect for a turbine regenerative type of pump. Factors that immediately identify your application and pump type are: the small flowrate, low NPSHa, and high temperature. The regenerative turbine was specifically developed for these conditions and one more: high discharge pressures. The high discharge pressure may not be necessary, but the regenerative turbine can give you a NPSHr of 0.5 feet with ease. They are particularly suited to saturated boiler feed water and your application is similar, albeit not in pressue. You can visit the site below to learn more about these types of pumps.

posted by Kipas Repair JB @ 8:28 PM,

,

![]()

Density Estimation for 2-Phase Mixture

What is a good correlation to estimate the density of a two-phase mixture that is mostly vapor or operating within the mist flow region?

Spink suggested the correlation below for qualities in the range of 0.82 to 1.0:

posted by Kipas Repair JB @ 8:13 PM,

,

![]()

Design of Experiment for Chemical Engineering Research

For those chemical engineering post graduate students whom are doing research, or who might plan of doing research, planning your research is very important. There will be a lot of experiments to be carried out. There must be a systematic way of doing all the tonnes of experiments. And one technique to do so is by using the Design of Experiment (DOE). My wife , Mazura, and a colleague of mine, Farizul, is going to use this tool for their pH.D research. I did used this as well during my Masters by reseach work few years ago.

DOE is a very useful technique to plan our research. From DOE we can optimize the research and know all the processing parameters that can yield optimum result. So what is actually DOE?

In an experiment, we deliberately change one or more process variables (or factors) in order to observe the effect the changes have on one or more response variables. The (statistical) design of experiments (DOE) is an efficient procedure for planning experiments so that the data obtained can be analyzed to yield valid and objective conclusions.

DOE begins with determining the objectives of an experiment and selecting the process factors for the study. An Experimental Design is the laying out of a detailed experimental plan in advance of doing the experiment. Well chosen experimental designs maximize the amount of "information" that can be obtained for a given amount of experimental effort.

The statistical theory underlying DOE generally begins with the concept of process models.

Process Models for DOE

It is common to begin with a process model of the `black box' type, with several discrete or continuous input factors that can be controlled--that is, varied at will by the experimenter--and one or more measured output responses. The output responses are assumed continuous. Experimental data are used to derive an empirical (approximation) model linking the outputs and inputs. These empirical models generally contain first and second-order terms.

Often the experiment has to account for a number of uncontrolled factors that may be discrete, such as different machines or operators, and/or continuous such as ambient temperature or humidity. Continue reading the article HERE. It's a very useful and informative one.

There a re various software/packages that offer DOE. Among them are using Statistica, Design Expert, DOE Fussion. So, incase you're interested to learn them, get hold of the software. You can start learning them from the help or tutorial available in the software. But, learning by yourself is quite slow. I know because I experienced that before. It's better for you to go through and then ask somebody who knows DOE. That will be a better way of learning. But if you/or your research group have the budget, request from your boss/supervisor to go for a dedicated course to learn DOE.

Ok, to go a little bit deeper, there are a few designs that can be choose under DOE. There are Plackett Burman Design, Response Surface Methodology (RSM) and others. I used RSM before and it was very usefull. I can have a lot of analysis generated infront of me by using RSM. It's a really fantastic tool.

posted by Kipas Repair JB @ 11:46 PM,

,

![]()

Boiler Explosion: What When Wrong? Part 2

Later the electrical and instrumentation department worked hard to dry everything at the control panel. The paint on top of the control panel were damaged and ripped off from the effect of hot caustic. The boilerman also worked hard to clean the mess and spillage in the surrounding area. The boiler was left for a while to let it cool down and dry.

Soon after about 2-3 hours, i guessed, instruction was given to start the boiler, at low fire mode, just to slightly heat up the mixture of caustic and water inside the boiler. The time was about 1430 Hrs, and I just arrived at the boiler and watching the boiler people doing their job. That was the time when the boiler exploded and produced such a terrifying sound!!

After investigation, it was found that burner A (it's a twin burner boiler), furnace backfired. The boilerman intended to run the burner at a low fire mode, but instead, without anybody realising, the burner which already contained with natural gas, straight away go to the high fire mode, which provided a big spark. That caused the explosion to occur which made the burner ripped off from the boiler body and created great damage around it. The boiler sequence actually when wrong, because of the short circuit in the control relay base from the earlier hot caustic spillage. When the short circuit occured undetected, the servo motor ignited the high fire mode, by passing the other sequence of low fire etc.

It costs a lot to repair the boiler. However, I solute our maintenance fitters, instrumentation and electrical technician, including boilerman because they work very hard to rectify and repair all the damage. Within a short period of time, about 36 hours, the burner (which was luckily can still be used) was re-attached at the boiler and all pipings, fittings, valves, gear etc was fixed back. We called some boiler expert to help us with the boiler sequence and start-up operation, and that cost some money too. Well, now the boiler is back in operation. And for sure, we'll be extra carefull from this moment to avoid similar or almost similar incident from occuring again.

I would definitely won't forget that moment. And another moral of the story, do not walk unnessarily nearby the boiler!!! Appreciate life...

posted by Kipas Repair JB @ 10:27 PM,

,

![]()

Boiler Explosion: What When Wrong?

After almost one week since the small boiler explosion occured, I asked my colleague the person incharge of the boiler, what is actually the reason the boiler exploded? I asked him just now, because the complete report from the specialist have been revealed.

Ok, we had some problem of some slight oil contamination inside the boiler water/steam. This is definitely not good. It can create some fluctuations in the steam production and also can cause wet steam which will result in pressure drop. And there are a lot more reasons on the bad effect of oil being inside the boiler.

So, the chemical vendor suggested us to do the Caustic Boiling. It's a method to removed completely any traces of oil inside the boiler. So, we did it. I did mention what chemical we blended and poured inside the boiler. The chemical is supposed to be mixed and boiled inside the boiler at temperature ranging from 60 - 70 oC. The feed water temperature is already about 80oC. Our superior advised to heat up the temperature so that the caustic can be thoroughly mixed with water inside the boiler via physical boiling technique. And guess what, the man-hole is not closed.

As the temperature increased gradually, the water + chemical is now almost boiled, and the water splashed out of the boiler man-hole. The hot water + hot mixture of various caustic

came out of the boiler man-hole and flowed down the external boiler body touching and covering the boiler control panel. Luckily my colleague bravely and swiftly shut off the boiler power/panel despite knowing that he can badly injured himself if the hot caustic fell and splashed on his body!!! Immedietly the electrical and intrument department were called to safe the control panel by drying it to avoid wire/electrical shot later.

posted by Kipas Repair JB @ 10:48 PM,

,

![]()

Colarado Underground Black Gold Questionmark?

On my previous post on the 4th of October 2006, I mentioned about why are we busy cracking our head to think of how to process, produce and commercialize vegetable oil as a renewable energy to replace the fossiel fuel. I met and discussed this matter with an American who happens to be a Endress + Hauser Manager who came to Malaysia conducting some training and seminar, 2 weeks ago.

He said the fact is correct. However, it is very difficult to get the oil from the shale. It may took some super technology to dig and get the oil. It may also take perhaps another 50 years to get the oil underneath Colarado!!! I don't know, this was what the guy said.

I asked my colleague who is a petroleum engineer about the issue. He said, oil inside a shale is very difficult to obtained due to the complexity of the earth/stone structure. The area which have oil is very porous and makes digging the oil very tough. About two years ago, when were having a chat, he said that the fossiel fuel reserve is so big down there. The problem is that the present technology to dig the oil is not there yet. We can only get the oil which is easy to dig!!! Therefore, the oil and gas sector need a more advance method and technology to produce oil which is still available.

And perhaps, in the mean time, the crops can help to ease the pressure of limited energy supply / resources, via biofuel / biodiesel. So, now my paradigm had shift again. Vegetable oil is important to support the energy demand, not replacing them.

posted by Kipas Repair JB @ 12:54 AM,

,

![]()

Preventing NaOH line from freezing

While I was clearing and updating my email, this is another interesting article that i read from the Cheresources newsletter.

Are there any guidelines for heat tracing a 50% NaOH line to prevent freezing?

Two very important things to keep in mind. First, be sure to place spacers between any heat tracing elements and the carbon steel pipe used for the NaOH. 50% NaOH will agressively attack carbon steel at higher temperatures (particularily any welds). Additionally, you really shouldn't use aluminum to cover the insulation on the line (a common material used for this purpose). Try stainless steel instead.

posted by Kipas Repair JB @ 1:06 AM,

,

![]()

Preventing Salt Buildup in Steam Turbine

This another interesting article that i read from the Cheresources newsletter.

How can we prevent what appears to be some kind of salt buildup in our steam turbine?

The problem that's occurring may not be a salt buildup. The most likely cause is silica buildup. Steam acts as a very good solvent for silica which actually can vaporize in your boiler along with the water. The solution to this problem is to minimize the silica content of your boiler feed water.

Experienced operators seems to agree that a maximum silica content of 0.02 ppm in the boiler feed water should solve this problem. You can read more about this issue at:

http://www.onlinewatertreatment.com/literature/Nalco/docs/Tf-005.pdf

posted by Kipas Repair JB @ 12:48 AM,

,

![]()

Heat of Dilution for NaOH solution calculation

Very interesting technical information that i got from Cheresources.com newsletter.

How can I calculate the heat of dilution for a sodium hydroxide solution?

posted by Kipas Repair JB @ 12:39 AM,

,

![]()

Commercializing Methane Hydrates

Mark your calendar now to attend one of the most important events of the year:

WHAT: Hart's Commercializing Methane Hydrates

WHEN: December 5 – 6, 2006

WHERE: Hotel Sofitel Houston in Houston, TX

WHY YOU SHOULD ATTEND: Commercial production of methane hydrates has become a high priority within the U.S. Government. As gas production in the U.S. struggles to keep pace with demand, it will become a priority within the industry.

Traditional thinking relegates production hydrates to the fairly distant future. However, many leading authorities now insist that first commercial production of methane hydrates can be accomplished in less than five years.

To learn how that can happen safely and profitably, plan to attend Hart's Commercializing Methane Hydrates, the first major conference on commercialization of the world's largest remaining untapped hydrocarbon resource.

Click here to view the article published in the September 2006 issue of E&P Magazine that discusses the issues surrounding commercial production of methane hydrates in more detail.

To find out more about the conference, sponsorships, and speaking opportunities for Hart's Commercializing Methane Hydrates, please click here.

Register now for Hart's Commercializing Methane Hydrates and take advantage of the Early Bird discounted registration fee. Click here to register.

I look forward to seeing you at the conference.

Sincerely,

Bill Pike

Editor in Chief, E&P Magazine

www.hartenergy.com

posted by Kipas Repair JB @ 10:59 PM,

,

![]()

Brownfields: Optimizing Mature Assets 2006 Conference

Brownfields: Optimizing Mature Assets 2006 Conference

Just passing the information from Hart Energy Conference:

Reserve your seat for Hart's Brownfields: Optimizing Mature Assets (BOMA). This year's BOMA 2006 will be held October 31 – November 1, 2006, at the Grand Hyatt Denver in Denver, CO.

Major topics at Hart's BOMA 2006 include:

* Driving efficiencies in infill drilling

* Water management

* Mature asset EOR/OR with an emphasis on CO2 flooding

* Optimizing artificial lift

* Advances in monitoring and modeling

* Emerging techniques and technologies for mature asset optimization

Click here to see the current agenda.

Click here to register.

I look forward to seeing you in Denver!

Best regards,

Bill Pike

Editor in Chief, E&P Magazine

www.hartenergy.com

posted by Kipas Repair JB @ 10:40 PM,

,

![]()

Centralize Control Room Dilemma

We are planning to have our centralize control room (CCR) in our group/factory. We plan to include SCADA and Manufacturing Execution System (MES) inside the picture. However, after some discussion with my superior, it seems quite complicated to incorporate SCADA and MES in the CCR. If we want to include MES, that will include production scheduling etc and a lot more departments such as operation, production, shiping etc. We think, those stuff are quite difficult to handle via MES because a lot of thinking are involve in a lot of critical daily decision making.

Therefore, i told my boss that we are actually not looking at MES and not SCADA as a whole, because SCADA will include some extent of human control via the human machine interface (HMI). What we want in the CCR is just some monitoring of the vital plant parameters, some analysis on the Overall Equipment Efficiency (OEE), Overall Plant Efficiency (OPE), things like downtime tracking, Key performance index (KPI), and probably some other stuff that I need to think of the make the CCR a really usefull, easy and imperative tool for the top management to use. Got to select the most vital plant tagging as well....Gosh....this is a very tough assignment for me!!!

posted by Kipas Repair JB @ 1:20 AM,

,

![]()

Terrifying Moment at Boiler House

Few days ago, I posted something about the condition in the boiler at the plant that i work in. We tried to solve the problem and after consulting with our water treatment boiler chemical vendor and his technical expert in America, it was decided to do a caustic boiling inside the boiler to remove all possible traces of oil which was suspected to be inside the boiler. We add up caustic, trisodium phosphate and sodium phosphate and heat up to about 60oC. After monitoring the chemical blending process and pouring the chemicals into the top manhole of the boiler, I leave the boiler and do some other jobs.

Later in the aternoon, after visiting the control room in my plant, I pay a visit to the boiler to see the progress there. I tried to ask to my colleague (the person in charge of the boiler), but he was busy doing something on the boiler control panel. At that moment, I was standing nearby and diagonal to the boiler. Suddenly, there was a very loud explosion. I can slightly see some red colour flame on my right. The incident happened very fast. I was on total shocked and immedietly tried to bend down to cover myself. Then I thought, I should seek cover to protect myself by hiding behind the small boiler house/room just on my left. It was difficult to open my eyes because of the smokes and thousands of fine particles/dust which were covering/flying around the area. I fear there might me a greater secondary explosion that might wipe off the boiler and surrounding area. If that had happened, we might be history!!!

When things became ok about 30 seconds to a minute later, I have a clear picture of what actually occured. I can see smokes and some people start gathering closer to check out the incident. The burner of the boiler which have few dozens of strong bolts holding them was lying on the ground next to the front of the boiler. Thick black coloured oil was expanding and flowing slowly from the burner. All the piping and other materials nearby the burner was damaged. It was not a nice scenery.

Then I saw some people coming down from top of the boiler. I was supprised that there were people there at that time. My colleague, the steam engineer, the chemical vendor and few maintenance fitter came down from the boiler and were supprised to see the burner was ripped off from the boiler body. At that moment, we were wondering, what caused the small explosion to occur? Investigation and theory on what went wrong began.

posted by Kipas Repair JB @ 8:11 PM,

,

![]()

Chemical Engineers Habit

I don't know about other graduate engineers or chemical engineers, but for me, as engineeers we need to have our target in career and profesion. We need to plan everything since the very beginning. We need to know our destiny. But, sometimes, it's difficult. Sometimes planning seems to be very easy, but the outcome might not be what we want.

Continuous learning is imperative for every engineers. For me I appreciate every knowledge around me. I love knowing new things. I set my own objective, or practice, which is to learn new things everyday. That's why everywhere I go, I'll bring along something to read. It doesn't matter wether the reading material is a book, magazine, printed paper or scribble of paper which i can read or develop ideas from it. I subscribe to a lot of free technical magazines in order to get new and fresh informations. There're a lot of those technical magazines that are available for me to read in my car as well. I read them when i stop at the traffic light!!! and during traffic jam!!! It's a dangerous habit, but I'm used to it....Among the free technical magazines are those that I have linked them on our the right hand column of this blog. Some of the magazine i subscribed online. That'll be easier too. As I checked and browse thru my email, I can read them too.

I'm happy and appreciate the pleasure to learn brand new knowledge everyday. I can post many things on my blog daily, but it's the time factor that prohibit me from doing so. Therefore, I only post something that I thing will benefit my guess and that's part of my intention, which is to share chemical engineering knowledges and experiences. If a chemical engineer does not have the desire or fire or excitement to learn and learn and continue learn...that's not a good sign!!!

For me he/she cannot develop and become a good knowledgeble chemical engineer.

My final say on this topic, ensure you learn new knowledge/ideas daily. Enrich yourself. Set your target. I set my target too. And my back-up target as well. Because life is not easy, sometimes we need plan B, plan C, plan D and so on..because plan A would not work!!!

I'm not saying that I'm a good engineer. But I want to become one. Let's do it and work it out together....

posted by Kipas Repair JB @ 9:31 PM,

,

![]()

Boiler Problem

Recently the utility boiler in my factory experienced some foaming problem. We knew foaming takes place when we see foam appeared in the water sample bottle. The water is taken from the autoblowdown line sampling point which takes out the surface boiling water inside the boiler. Although all the water parameters such as total dissolved solid (TDS), pH, alkalinity, phosphate, chloride content seems to be within control ranged the water chemical still create foam.

This is a great deal and matter because this can affect the steam demand and quality that will be consumed by all the plants in the factory. It can affect the production and cost a huge lost.

Although we have change the boiler water, the foam is still there, but at least the foam will dissipate and disappear faster than before, showing sign of improvement. However, my concern and hope is to see zero foam appears from the sample water. Well, we are still trying our best with the help of our boiler chemical supplier to eliminate the problem. I hope the problem will be solved soon.

posted by Kipas Repair JB @ 1:06 AM,

,

![]()

Interesting Quote

"If we all did the things we are really capable

of doing, we would literally astound ourselves."

* Thomas Alva Edison *

posted by Kipas Repair JB @ 12:38 AM,

,

![]()

Sudden Pigging Job

Today I called a friend of mine whom i worked with in my previous company, "Complete Oilfield Stimulation Services" (COSS), an oil and gas servicing company. We have a chat and catched up a little bit with some news and info about the the jobs, projects and company.

He asked for my help. I said, what it is? He asked whether I'm free next week? Between Wednesday till the weekend. I asked him what actually he wants me to do? Then he explained...He wanted me to join him and his team to go to Songkla, Thailand to do the pig retrieval job there. I was supprised when he asked that sort of favour from me.

The 36" filming pig was launched from Cakerawala Platform at the border of Malaysia and Thailand about 1 week ago. It was COSS first trial project there and their first attempt to go international. I was working with COSS previously for about 2 and a half years and i handled a lot of pigging jobs there, but i have not handle any international pigging job yet. This might be an interesting and exciting job to participate.

The problem that my colleague have is he does not have any manpower who have the international passport and expertise to perform and manage the job. That's why, when i called him, he immedietly ask the favour from me. Though I'm dying inside to go and venture a new experience in a new place, I can't go. I have a lot of works, projects and a plant to take care and handle in my existing company that i work now. It's a actually a blow for me. And i know, my boss would never let me take any anual leave that long.

I just wish that I can have a more flexible job that I can freely perform any other technical jobs/projects if invited without affecting my present job. Would that be wonderful?!! I can further develop my overall skills and career.

posted by Kipas Repair JB @ 10:34 PM,

,

![]()

Vegetable Oil - Food or Fuel - The Future

I have been reading few articles in the past few days relating to oil/fuel. While there's some hope and potential of the vegetable oil like soy bean, rape seed, palm oil, jatropa, and others to be converted as fuel, they are also well known establish food resources. And now, it depends on the world, or maybe to narrow it down, politician rather than scientist to decide on the priority between food or fuel. It will be a lengthy discussion and debate. And perhaps, it's going to be a difficult and tough issue. All of this, a direct result of the depletion of fossil fuel. The reserve which might last for maybe 20-30 or 40 years more, has created staggering urgency to seek renewable energy resources. And as thinking people, we keep thinking and wandering about it....because i believe that vegetable oil will have certain role in the fuel market demand.

In conjunction with that, I was wandering to get some piece of land and plant them with the likes of palm oil and sugar cane mainly because the huge potential of profit that i can gain later. I know, if i have some 10 - 20 acres of land planted with those crops, i can channel them into a variety of products. I can make massive fortune from it, and expand it further from there. Because of that too, i'm slowly learning the kitchen scale biodiesel process....ha ha....

While I was wandering and experimenting the theoretical part of converting used cooking palm oil to diesel, i was struck with the information that the fossil fuel reserve in America is substantially huge. The reserve is more than what the midde east are having now. If I recall correctly, the fossil reserve is about 3 trillion barrels or probably more, and can ensure continuous supply of petroleum (gasolline/diesel/etc) for another 500 years!!!

After reading that, I thought again, what the heck are we doing cracking our head and brain cells to think and develop the biodisel/biofuel industry/technology after knowing that there are a lot of black gold underneath Colarado, USA!!! Opss....ok...at least for the sake of knowledge and new tech.

With this piece of information....for me......there would be NO MORE ISSUE of vegetable oil debate: Food or Fuel....at least for the next 500 years!!!!

posted by Kipas Repair JB @ 10:49 PM,

,

![]()

The Author

I’m Zaki. I used to be a project, process and chemical engineer. Few years ago I successfully became a Chartered Engineer (IChemE) and Professional Engineer (BEM). I'm now employed as a chemical engineering educator/researcher/consultant. Hope you like reading my blog. I welcome any feedback from you. My email: zaki.yz[alias]gmail.com. TQ!